Production

The cold-rolling process is a machining process without pre-heating the steel, which reduces the thickness of the rolled steel.

This processing generates steels with better mechanical strength and surface finish.

Albasider is able to supply its customers with plates, tapes and straps in thicknesses between 0.40 and 3 mm.

| Cold rolled | ||

|---|---|---|

| Processing | Thickness | Width |

| Plates | 0,40 - 3 | ≤ 2000 |

| Tapes | 0,40 - 3 | ≤ 2000 |

| Straps | 0,40 - 3 | 180 - 2000 |

Cold-forming and drawing steels

These steels are used for deep and very deep drwaing, with excellent formability.

Due to their low carbon content, they have a good aptitude for welding.

The higher the grade chosen, DC01 ==> DC06, the greater the material’s propensity for deep drawing.

Main fields of application

- Household appliances

- Automotive and transport

- Shelving

- Air conditioning

- Tubes

- Small profiles

Enamelling steels

Enamelling steels are produced by special processes that allow strict control of the chemical composition and microstructural characteristics. These characteristics give the material the ability to withstand the stresses induced by the enamelling process, reducing gaseous emissions during enamel firing and ensuring perfect adhesion. EK grades are suitable for conventional enamelling. ED grades are characterised by almost complete decarbonisation and are more suitable for direct enamelling. As with deep-drawing steels, the higher the desired grade, DC01 ==>DC06, the greater the material’s propensity for deep drawing.

Main fields of application

- Household appliances

- Industry

- Architectural applications

High strength steels

High strength steels are characterised by a low carbon content and other microalloying elements. The degree of hardening, achieved through internal molecular structure control for high purity, gives these steels high mechanical strength. The result is excellent weldability and formability.

Main fields of application

- Profiles

- Industry

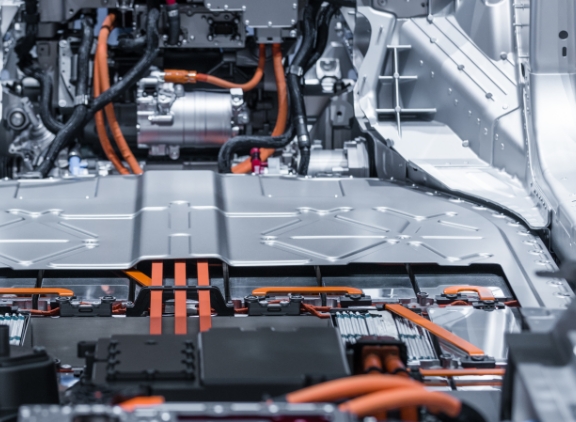

- Automotive and transport

- Industrial supplies

- Mechanical applications