Production

Following cold rolling, the rolled product can be coated with a layer of zinc on one or both sides by means of an electrostatic deposition process. The coating by this method is thus uniform and with a constant thickness.

The electrogalvanising process allows the steel substrate to be uniformly protected from atmospheric corrosion and to have an excellent weldability.

Albasider can supply its customers with electro-galvanised plates, tapes and straps in thicknesses between 0.4 and 3 mm.

| Hot Rolled | ||

|---|---|---|

| Processing | Thickness | Width |

| Plates | 0,40 - 3 | ≤ 2000 |

| Tapes | 0,40 - 3 | ≤ 2000 |

| Straps | 0,40 - 3 | 180 - 2000 |

Cold-forming and

drawing steels

These steels are used for deep and very deep drwaing, with excellent formability.

Due to their low carbon content, they have a good aptitude for welding.

The higher the grade chosen, DC01 ==> DC06, the greater the material’s propensity for deep drawing.

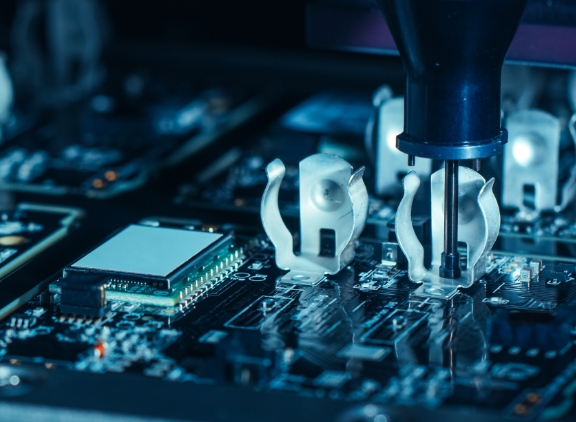

Main fields of application

- Household appliances

- Industry

- Electronics

- Civil and industrial supplies

High yield strength steels

Following cold rolling, the rolled product can be coated with a layer of zinc on one or both sides by means of an electrostatic deposition process. The coating by this method is thus uniform and with a constant thickness.

The electrogalvanising process allows the steel substrate to be uniformly protected from atmospheric corrosion and to have an excellent weldability.

Albasider can supply its customers with electro-galvanised plates, tapes and straps in thicknesses between 0.4 and 3 mm.

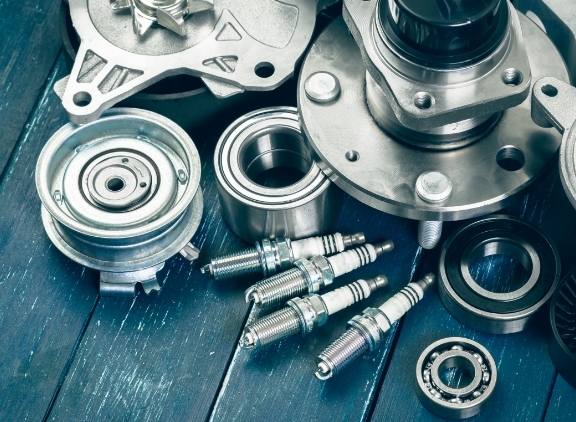

Main fields of application

- Automotive

- Industry

- Construction