Production

The galvanised coating consists of a high-temperature bath of molten zinc, continuously applied to the steel substrate by means of a laminate immersion process.

This type of coating provides excellent corrosion resistance while simultaneously ensuring formability of the material and weldability.

| Hot-coated |

||

|---|---|---|

| Processing | Thickness | Width |

| Plates | 0,40 - 3 | ≤ 2000 |

| Tapes | 0,40 - 3 | ≤ 2000 |

| Straps | 0,40 - 3 | 180 - 2000 |

Cold-forming and drawing steels

The coated forging steels category allows users to have excellent performance in terms of deep drawing, bendability and formability. In addition to these mechanical characteristics, the chosen coating allows protection from oxidation even after the material has been processed.

The higher the grade chosen, DX51D ==> DX57D, the greater the material’s propensity for deep drawing.

Main fields of application

- Household appliances

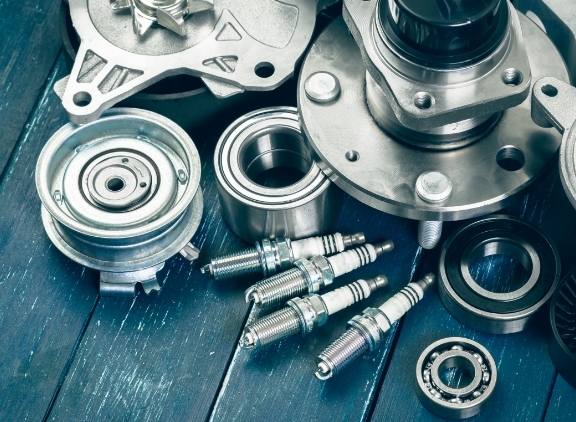

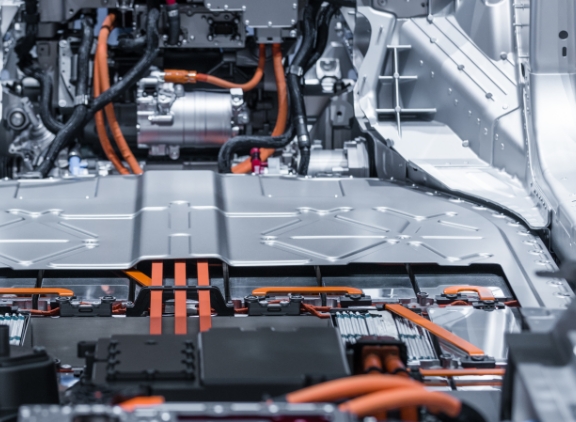

- Automotive and transport

- Industry

- Civil and industrial supplies

- Air conditioning

- Tubes

- Profiles

Structural steels

Main fields of application

- Construction

- Automotive and transport

- Civil and industrial supplies

- Mechanical carpentry

- Profiles

High-strength steels

Also called micro-alloy steels, in addition to a low carbon content they have a high purity internal molecular structure.

Due to their low carbon content, they exhibit improved weldability.

The ductility, fatigue resistance and formability of these steels offer high performance at a low weight

Main fields of application

- Construction

- Agricultural machinery

- Carpentry

- Profiles

- Automotive and transport

Bake hardening steels

Bake hardening steels allow for a higher level of mechanical strength with the same thickness. This effect is obtained through a process called Bake Hardening Response (BHR), which guarantees a particular hardening of the material, through an annealing heat treatment, carried out after deformation and painting of the material.

The great advantage of these products is that they initially show a not particularly high yield strength, which allows even complex machinings to be carried out. Following the machining and painting process, depending on the deformation imparted, the final part has a higher mechanical strength. This also results in high fatigue and impact resistance.

Main fields of application

- Automotive and transport